Details

Standard ratio beta rr 2t. 250 13-20: 13Standard ratio beta rr 2t. 300 13-18: 13Standard ratio beta rr 4t. 250 05-06: 14Standard ratio beta rr 430 15-18: 13Standard ratio beta rr 450 13-13: 14Standard ratio beta rr 480 15-20: 13Standard ratio beta rr 4t. enduro 350 11-12: 13Standard ratio beta rr 4t. enduro 350 13-20: 13Standard ratio beta rr 4t. enduro 400 05-10: 13Standard ratio beta rr 4t. enduro 450 05-12: 14Standard ratio beta rr 4t. enduro 520 05-10: 14Standard ratio beta xtrainer 300 15-18: 13Standard ratio husaberg fe 250 13-14: 14Standard ratio husaberg fe 390 10-11: 13Standard ratio husaberg fe 501 13-14: 14Standard ratio husaberg fe 570 09-12: 13Standard ratio husaberg te 250 10-14: 13Standard ratio husaberg te 2t 125 11-14: 13Standard ratio husaberg te 300 10-14: 13Standard ratio husqvarna fc 250 14-21: 14Standard ratio husqvarna fc 350 14-19: 14Standard ratio husqvarna fc 350 20-21: 14Standard ratio husqvarna fc 450 14-15: 13Standard ratio husqvarna fc 450 16-19: 13Standard ratio husqvarna fc 450 20-21: 13Standard ratio husqvarna fe 250 14-19: 13Standard ratio husqvarna fe 250 20-20: 14Standard ratio husqvarna fe 350 14-21: 14Standard ratio husqvarna fe 450 14-15: 13Standard ratio husqvarna fe 450 16-19: 14Standard ratio husqvarna fe 501 14-15: 14Standard ratio husqvarna fe 501 16-19: 14Standard ratio husqvarna fx 350 17-19: 14Standard ratio husqvarna fx 450 17-19: 13Standard ratio husqvarna tc 125 14-19: 13Standard ratio husqvarna tc 125 20-21: 13Standard ratio husqvarna tc 250 14-15: 13Standard ratio husqvarna tc 2t 250 16-20: 14Standard ratio husqvarna te 250 14-17: 14Standard ratio husqvarna te 300 14-21: 13Standard ratio husqvarna te 310 11-13: 13Standard ratio husqvarna te i 150 20-20: 13Standard ratio husqvarna tx 125 17-19: 13Standard ratio husqvarna tx 300 17-19: 13Standard ratio ktm exc (4t) 500 13-19: 14Standard ratio ktm exc 250 10-11: 14Standard ratio ktm exc enduro 125 00-02: 14Standard ratio ktm exc enduro 125 03-10: 14Standard ratio ktm exc enduro 125 12-16: 14Standard ratio ktm exc enduro 125 91-97: 13Standard ratio ktm exc enduro 125 98-99: 13Standard ratio ktm exc enduro 200 02-02: 14Standard ratio ktm exc enduro 200 04-06: 14Standard ratio ktm exc enduro 200 07-10: 14Standard ratio ktm exc enduro 200 12-14: 14Standard ratio ktm exc enduro 200 98-99: 14Standard ratio ktm exc enduro 250 00-03: 15Standard ratio ktm exc enduro 250 04-04: 13Standard ratio ktm exc enduro 250 05-06: 14Standard ratio ktm exc enduro 250 12-20: 14Standard ratio ktm exc enduro 250 91-94: 14Standard ratio ktm exc enduro 250 95-95: 13Standard ratio ktm exc enduro 250 96-99: 14Standard ratio ktm exc enduro 300 04-04: 13Standard ratio ktm exc enduro 300 05-10: 13Standard ratio ktm exc enduro 300 12-19: 14Standard ratio ktm exc enduro 300 95-97: 14Standard ratio ktm exc enduro 300 98-98: 14Standard ratio ktm exc enduro 300 99-03: 14Standard ratio ktm exc enduro 360 96-97: 14Standard ratio ktm exc enduro 380 00-00: 15Standard ratio ktm exc enduro 380 01-02: 14Standard ratio ktm exc enduro 380 98-99: 14Standard ratio ktm exc enduro racing 400 99-05: 14Standard ratio ktm exc enduro racing 520 01-02: 14Standard ratio ktm exc enduro racing 520 99-00: 14Standard ratio ktm exc racing 250 02-02: 14Standard ratio ktm exc racing 250 03-03: 14Standard ratio ktm exc racing 250 04-06: 15Standard ratio ktm exc racing 450 04-11: 15Standard ratio ktm exc racing 525 04-07: 15Standard ratio ktm exc tpi 150 20-21: 13Standard ratio ktm exc-f (4tempi) 250 08-11: 14Standard ratio ktm exc-f (4tempi) 250 12-21: 14Standard ratio ktm exc-f 350 13-19: 13Standard ratio ktm exc-f 450 17-20: 14Standard ratio ktm exc-r 530 08-11: 15Standard ratio ktm freeride 250r 14-19: 12Standard ratio ktm freeride 350 12-16: 11Standard ratio ktm smr 450 04-06: 14Standard ratio ktm smr 525 04-04: 14Standard ratio ktm smr 560 06-07: 14Standard ratio ktm smr supermoto 450 08-14: 14Standard ratio ktm sx 150 10-14: 14Standard ratio ktm sx 150 15-17: 14Standard ratio ktm sx 200 02-06: 14Standard ratio ktm sx -f (factory edition) 450 13-15: 14Standard ratio ktm sx-f (505) 500 08-09: 14Standard ratio ktm sx-f 350 10-19: 14Standard ratio ktm sx-f 350 20-21: 14Standard ratio ktm sx-f 450 13-15: 14Standard ratio ktm sx-f 450 20-21: 13Standard ratio ktm xc 250 12-14: 14Standard ratio ktm xc 250 15-19: 13Standard ratio ktm xc 300 15-19: 13Standard ratio ktm xc tpi 250 20-21: 13Standard ratio ktm xc-f 250 12-19: 13Standard ratio ktm xc-f 250 20-21: 13Standard ratio ktm xc-f 450 13-15: 14Standard ratio ktm xc-f 450 16-21: 13Standard ratio ktm xc-w 125 17-19: 13Standard ratio ktm xc-w 150 17-17: 13Standard ratio ktm xc-w 200 06-16: 14Standard ratio ktm xc-w 250 12-16: 13Standard ratio ktm xc-w 250 17-17: 14Standard ratio ktm xc-w 250 18-19: 13Standard ratio ktm xc-w 450 12-15: 13Standard ratio ktm xc-w tpi 150 20-21: 13Standard ratio ktm xc-w tpi 250 19-21: 14Standard ratio ktm xc-w tpi 300 19-21: 14

In the list above, when not indicated, the item is for standard chain.

PBR manufacturers in Italy and sells motorcycle sprockets (front and rear sprockets, chains and complete kits) and wide range of accessories (handlebars, clip-on handlebars, handlebars weights, handlebar clamp kits, bike stand knobs, chain grease and cleaner, crash pads and mecdraulic).

We take part at the most important national and international competitions and events.

Thanks to our presence on the international markets, our well-know brand, our competence and our service we are the first choice of the major market operators.

All this could be enough to sum up our activity during the last quarter of century, but it is also right to mention that this is the result of years of research and development, tests, technical improvements, careful selection of raw materials and production processes, combined with the manual ability of specialized craftsmen along with the high precision of CNC industrial technologies.As a result, special productions of prototypes and models for racing purposes are possible together with series production capacity for the industrial market.

Remember to select the right ratio in the products options.

Front Sprockets (counter shaft) are made of chromoly steel, machined all over for accuracy. Many of these are available drilled and machined for lightness. (normally 520 and 415)

Rear sprockets are essentially two types: stainless steel and aluminum.

Every sprocket is made on precision, computer controlled equipment. The teeth are machined to the latest standards, for maximum chain life and more efficient power transmission. The teeth and the outside diameter are cut at the same time. This makes sure the teeth are concentric to the sprocket center.

Every sprocket is made from heat treated 7075-T6 aluminum, hard anodized finished for extra durability

- Steel: ideal replacement of the OEM part, where quality is not better is the same of the original.

Every sprocket is heat treated through an induction hardening then tempered to produce exactly the correct hardness for durability and efficient power delivery. To correct any distortion that may have occurred during these stages, the sprockets are put through a special flattening machine. For corrosion resistance, the steel sprockets are bright zinc plated.

- Aluminum: the max for those who want to light final transmission or have on board an accessory that on expert riders have. Usually we have on stock 520 or 415 sprockets but original pitch could be ordered.

Made from heat treated 7075-T6 aluminum we offer them only hard anodize finished for an extend life time.

Example front sprockets machined for lightness:

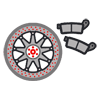

Example rear stell sprocket:

Example rear ergal sprocket:

Example rear ergal colored sprocket:

Example rear ergal hard racing sprocket:

By choosing the ratios, 1 front sprocket cog is equal to about 3 rear sprocket cogs (the exact ratio is given by: number of rear sprocket teeth / number of front sprocket teeth).

The above stated, ratios have to be chosen in a way that a max. difference of 2 cogs is not exceeded. This way, you can always keep the same chain length. The Kawasaki ZX-10R Ninja is an exception: a rear chain with over 1 tooth more than the stock one cannot be used, since length of stock chain will not allow that. Remember that if you want more acceleration you have to mount a rear sprocket with more toothing, or a front sprocket with lower toothing. Ratios have to be necessarily and exclusively chosen by yourself. It is usual to mount a rear sprocket with 2 teeth more than the stock one, but that is however a medium choice which does not mean to be satisfying to everybody.

In a circuit, generally the right final ratio will be that allowing to achieve, at the highest gear, about 200 rpm more than the max power rate, always staying 200 / 300 rpm under the maximum rate the engine can reach. This way, you can take advantage of the trail of the driver who is preceding you.

Choosing the final ratio, remember that the bigger it is, the more the acceleration will be. But if it is too big, you will lose speed. If on the contrary the ratio is too small, you will lose acceleration and will not manage to reach the maximum speed.

If your final transmission has exceeded 5000 km, we advise not to change only one of the three components, but to change them altogether (chain,rear and front sprockets). This, because final transmission would otherwise deteriorate in very few kilometres.

For the best working and longer duration of the transmission, it needs to be cleaned and lubricated every 1000 Km at least, using our specific cleaner and lubrificant for chains that you find here.

PBR's catalogue

PBR's catalogue

- Compatible model years

- Husqvarna FC 250 2014

- Husqvarna FC 250 2015

- Husqvarna FC 250 2016

- Husqvarna FC 250 2017

- Husqvarna FC 250 2018

- Husqvarna FC 250 2019

- Husqvarna FC 250 2020

- Husqvarna FC 250 2021

For your moto

For your moto  Moto Parts

Moto Parts  Alu7075 accessories

Alu7075 accessories  Fairings & Carbon parts

Fairings & Carbon parts  Wheels and tyres

Wheels and tyres  Controls and levers

Controls and levers  Windscreens & windshields

Windscreens & windshields  Brakes

Brakes  Garage & Track

Garage & Track  Electrical parts

Electrical parts  Engine parts

Engine parts  Frame parts

Frame parts  OFF-ROAD plastic kits

OFF-ROAD plastic kits  License plate holder

License plate holder  Protections

Protections  Exhausts

Exhausts  Seats & seat covers

Seats & seat covers  Shocks

Shocks  View mirrors

View mirrors  Trasmission

Trasmission  Products for all Moto

Products for all Moto  Off-Road accessories

Off-Road accessories  Race accessories

Race accessories  Touring accessories

Touring accessories  Accessories Handlebars

Accessories Handlebars  Accessories Electronics

Accessories Electronics  Accessories Brake M.C.

Accessories Brake M.C.  Action Camera

Action Camera  Stickers and Tank pads

Stickers and Tank pads  Anti-theft and Disc Lock

Anti-theft and Disc Lock  Tools and equipment

Tools and equipment  Batteries

Batteries  Chargers and accessories

Chargers and accessories  Chain

Chain  Stands & Ramps

Stands & Ramps  Quick throttle controls

Quick throttle controls  Indicators

Indicators  Lights & Universal light

Lights & Universal light  Grips

Grips  Handlebars

Handlebars  Merchandising & Gadgets

Merchandising & Gadgets  Oil for your bike

Oil for your bike  Brake calipers

Brake calipers  Universal plastics

Universal plastics  Tyres

Tyres  Clutch pump & control

Clutch pump & control  Front brake Master cylinder

Front brake Master cylinder  Rear brake Master cylinder

Rear brake Master cylinder  Clean and care

Clean and care  Spare parts carburetors

Spare parts carburetors  Spare parts

Spare parts  Spare parts for exhaust and silencers 2T

Spare parts for exhaust and silencers 2T  Suspension parts

Suspension parts  Exhaust SC-Project

Exhaust SC-Project  Racing bars

Racing bars  Mirrors

Mirrors  Electronic equipment

Electronic equipment  Tyre warmers

Tyre warmers  Transporting bikes

Transporting bikes  Bolts

Bolts  Gift card

Gift card

Oil

Oil  Motor oil 4T

Motor oil 4T  Motor oil 2T

Motor oil 2T  Chain lube

Chain lube  Fork oil

Fork oil  Brake fluid

Brake fluid  Air Filter oil

Air Filter oil  Coolants

Coolants  Sintoflon products

Sintoflon products  Lubrificant & Degreaser

Lubrificant & Degreaser  OFF ROAD gear

OFF ROAD gear  Helmets Off-Road

Helmets Off-Road  Trial Helmets

Trial Helmets  Junior Helmets

Junior Helmets  Off-Road Goggles

Off-Road Goggles  Lens and Accessories's Goggles

Lens and Accessories's Goggles  Gloves

Gloves  Jersey

Jersey  Pants

Pants  Junior Clothing

Junior Clothing  Boots

Boots  Junior Boots

Junior Boots  Socks

Socks  Chest Protector

Chest Protector  Knee guards

Knee guards  Neck protections

Neck protections  Elbow & shoulders protections

Elbow & shoulders protections  Back protectors

Back protectors  Junior protections

Junior protections  Technical Clothing

Technical Clothing  Jackets

Jackets  Rainproof

Rainproof  Clothing cleaners and detergents

Clothing cleaners and detergents  Bag and Backpack

Bag and Backpack  Waist packs

Waist packs  Camelbak Hydration Packs

Camelbak Hydration Packs  ROAD gear

ROAD gear  Helmets full face

Helmets full face  Helmets touring and modular

Helmets touring and modular  Helmets jet and demi-jet

Helmets jet and demi-jet  Junior Helmets

Junior Helmets  Road gloves

Road gloves  Women' s road gloves

Women' s road gloves  Racing Boots

Racing Boots  Touring Boots

Touring Boots  Women's boots

Women's boots  Shoes

Shoes  Women's shoes

Women's shoes  Road jackets

Road jackets  Road pants

Road pants  Technical Clothing

Technical Clothing  Back protectors

Back protectors  Knee sliders

Knee sliders  Rainproof

Rainproof  Casual Clothes

Casual Clothes  Helmet Garmet bags

Helmet Garmet bags  Clothing cleaners and detergents

Clothing cleaners and detergents  Shoes motorcycle

Shoes motorcycle  Bike

Bike  Bike Helmets & Clothing

Bike Helmets & Clothing  Bike Accessories

Bike Accessories  Tools & Maintenance Bike

Tools & Maintenance Bike  Parts & Components Bike

Parts & Components Bike  Gift Card

Gift Card